Characterization of optical coatings

An optical coating consists of thin layers of various materials on the surface of an optical component like a window or lens. Optical coatings work in a limited wavelength range by reflecting a fraction (R) of incident light while transmitting the rest (1-R). The purpose of coatings is to protect the surfaces of optical components or to improve their properties.

For example, testing laser line filter transmittance, increasing solar cells’ lifespan, measuring and monitoring lighting reflectors, motion detectors, or telecommunications systems are just some of the applications of optical coatings that have been developed for several industries.

Coatings are manufactured by depositing thin layers of alternating materials in a well-controlled vacuum environment. Vacuum deposition can be achieved by vaporizing a solid or liquid coating material in vacuum. In the process of vaporization, atoms or molecules are deposited on the surface of the optical component that needs to be coated.

Anti-reflective (AR) and high-reflective (HR) coatings are two types of coatings used in optical systems across most wavelength bands.

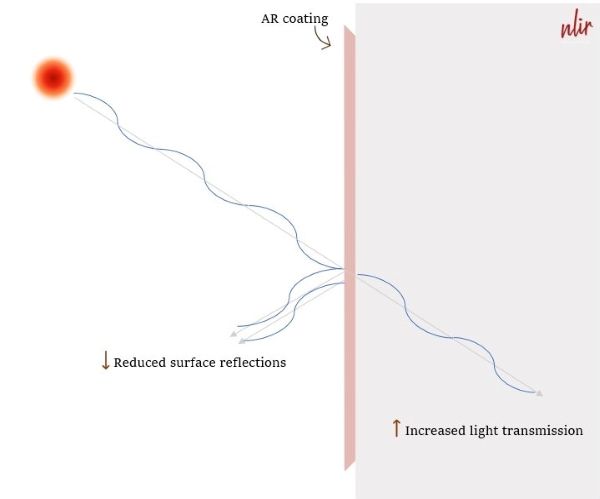

AR optical coating

The application of AR coating reduces surface reflections by increasing light transmission. Various applications, including display panels, solar cells, and optical lenses, incorporate antireflection coatings due to reduced reflection.

HR optical coating

In the case of HR coatings, they are increasing reflectivity where it is needed. For that reason, highly reflective coatings have extensive application potential in products that are sensitive to heat damage. Among many applications of reflective coatings are beam splitters, which create mirror surfaces that reflect infrared radiation back to their sources.

The development of optical coatings has been extremely rapid, and especially for infrared materials.

The term infrared (IR) optical coating refers to the coating procedure for light in the infrared spectrum, from 740 and beyond 25000 nm wavelength. Applications include high-power lasers, thermal cameras, and airborne imagers.

The quality, performance, and effectiveness of optical coatings are influenced by the uniformity and thickness of the material. In IR coating materials, spectral transmission and chemical composition differ. A material that is used for IR radiation is less mechanically durable than one that is used for shorter wavelengths, or visible light. In terms of chemical composition, the materials vary widely. In order to achieve the necessary durability and functionality of thin film coatings, the arrangement, type, and ratio of atoms in molecules of chemical substances must be measured and evaluated in depth.

Why fast, sensitive, and accurate spectroscopy in optical coating measurements?

Fast and accurate optical measurements are needed to achieve depth coating analysis during the production process. The most common measurement tool used for spectral optical testing is a spectrophotometer. Spectrophotometers with high accuracy, speed, and resolution are ideal for measuring the transmission, reflection, scattering, and absorption of light on optical coatings.

In the IR spectral range, many different molecules have very strong absorption properties. High-speed, high-resolution, and ultrasensitive IR spectrometers are the best option for measuring optical film thickness and measuring the uniformity of film thickness across coated surfaces.

- Fast spectrometers enable the study of light transmission, and absorption occurring under production and/or post production QA inspection.

- High sensitivity is essential for the accurate detection and characterization of various molecules. In addition, it reduces the requirements for high-brightness light sources.

- High-resolution spectrometers can monitor narrow-bandpass filter growth and eliminate substrate interference errors.

NLIR’s spectrometer 2.0-5.0 μm combines speed, high sensitivity, and high resolution providing innovative revolutionary solutions in IR coating quality control and production monitoring.

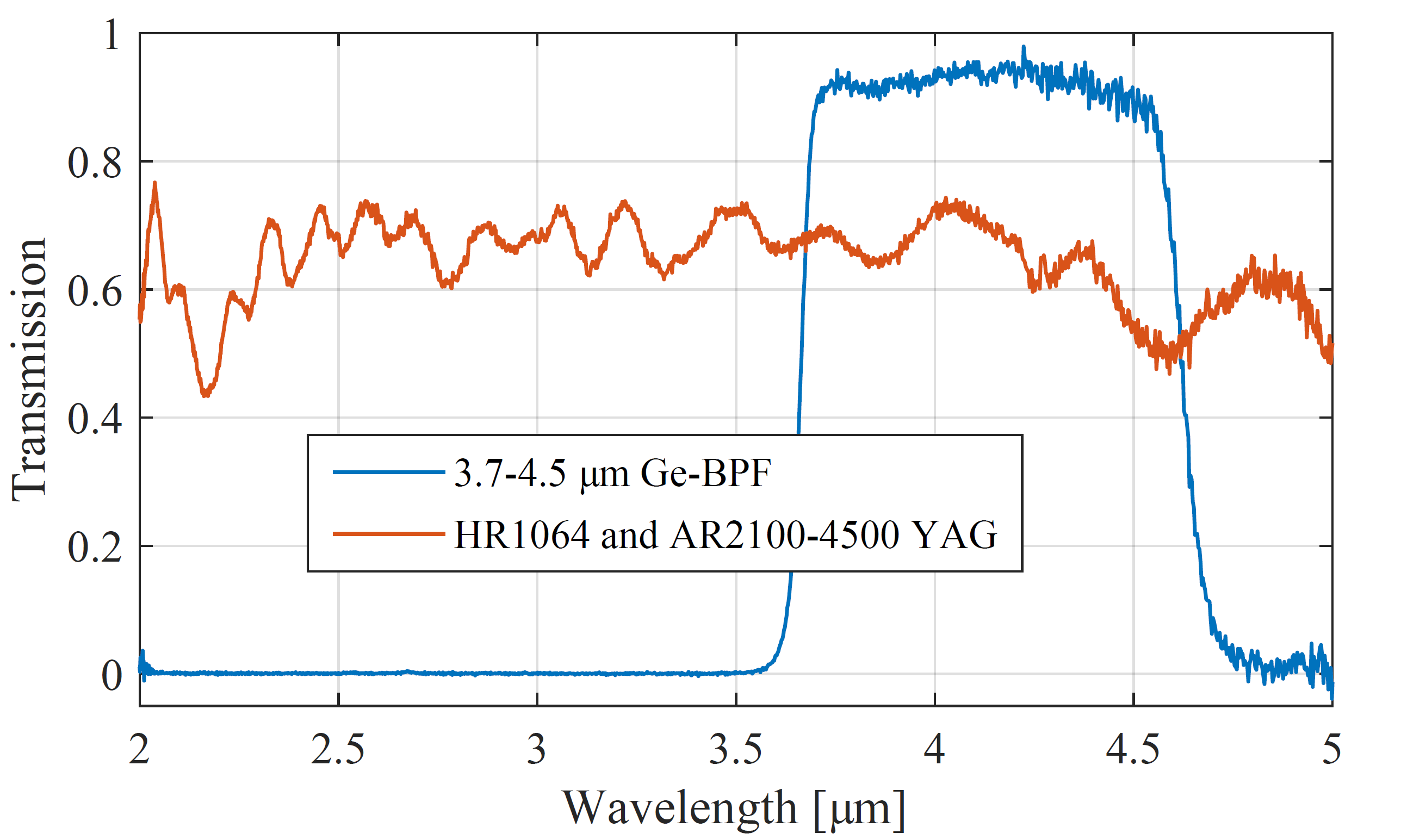

Optical Coating Transmission with the S2050-400

A 30 W globar was used as the light source for these transmission measurements of coated optical windows: a Ge bandpass filter (BPF) for 3.7 – 4.5 µm and a YAG mirror coated with high reflection at 1064 nm and high transmission at 2.1 -4.5 µm. The S2050-400 spectrometer was set to 20 ms exposure time and captured just single shots. No averaging or smoothing has been applied to the data subsequently.

Why choose S2050 spectrometer for your optical coating application?

- Up to 130 kHz readout rate

- -80 dBm/nm sensitivity

- Down to 5 cm-1 resolution