Sample Probing with Optical Fibers

Sample probing with optical fibers for small samples: light is reflected by the sample and is transmitted back to the spectrometer via another fiber.

In both high-tech and conventional industries, many products or samples are of a small or inaccessible nature, which makes them inherently difficult to inspect during production and quality assessment.

Some examples of applications include:

- the production of silicon wafers

- the inspection of small optical components for integrated optics (fiber inspection)

- measurements in hot environments and vacuum chambers

- characterization of gemstones

For all these applications, optical fibers are a convenient way to bring light to and from a sample for optical characterization. In addition, this method provides all the knowledge and possibilities for automated monitoring. In the visible and near-infrared (near-IR) regimes of light, fibers, light sources, and measurement instruments have been extensively developed and continue to be so. Nevertheless, in the mid-infrared (mid-IR) range, where molecules interact more strongly with probe light, the choice of equipment is limited and is therefore used to a lower degree in many industries.

Industry requirements for optical probing

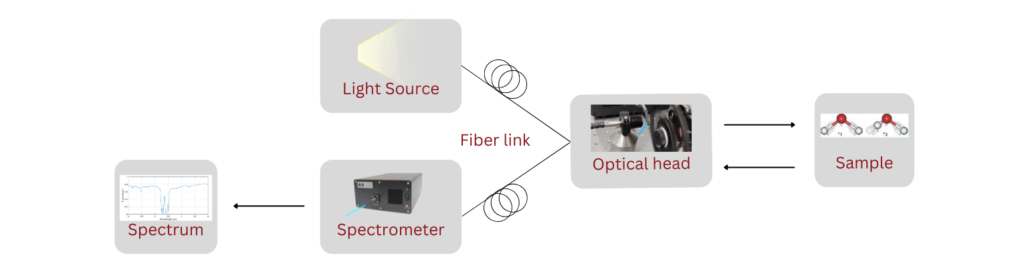

To perform sample inspection with mid-IR light, a mid-IR light source, fiber optic probes, and a spectrometer are needed. This set of equipment can give detailed information about the state or quality of the sample under inspection. The light that returns from the sample provides valuable information on which specific molecular composition dominates the sample. Even small concentrations of molecules can be measured. Analysis of these data from a spectrometer will reveal such information.

For research purposes, the most significant properties of a mid-IR spectrometer are resolution, sensitivity and stability, and such high-end spectrometers are available from a range of suppliers. For industrial applications, however, these properties are of course desirable, but just as critical are robustness to the surrounding environment, price, and perhaps most importantly speed.

In a production line with either many or very large samples, it is of very high importance that:

- A spectrometer can run undisturbed by high (or low) temperatures and unavoidable vibrations present in a production facility. This is the greatest obstacle in bringing conventional FTIR instruments into production facilities.

- A reasonable price is set. The price of a single instrument is usually not of paramount importance. However, companies often hesitate to start investing in expensive equipment when many devices are needed, which is often the case on production lines.

- There is enough speed for the production to run smoothly. Monitoring production in an industry 4.0 framework must work at the same pace as existing production so as not to become a bottleneck which can end up costing more than it saves.

NLIR’s solution

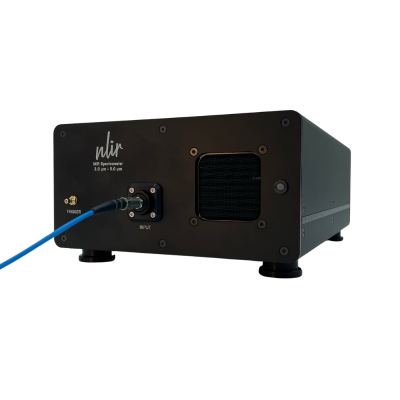

NLIR’s mid-IR spectrometer S2050 series is designed to fit into an industrial setting: it’s the fastest mid-infrared spectrometer commercially available and it has no moving components, making it very vibration tolerant. It is fiber coupled, very sensitive, and has good resolution for many applications.

Optical transmission between probe and interface

Another key feature of a measurement setup is the optical interface. There are many different solutions commercially available depending on the nature of the sample: solid surfaces typically use direct transmission between fiber and fiber or reflection at an angle. Liquid compounds are commonly measured using an attenuated total reflection (ATR) crystal, which may or may not be fiber coupled. Different fiber sizes and materials are available, and bundles are made to bring light to and from the sample. The right solution depends on the sample under consideration.

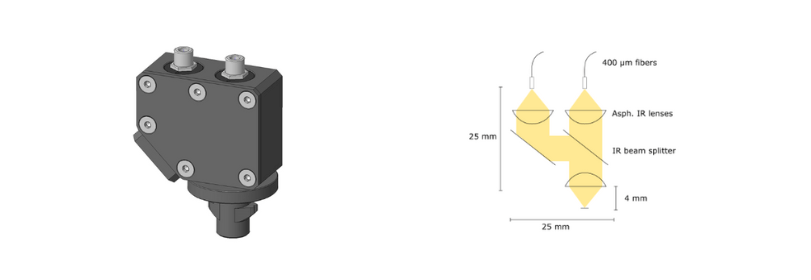

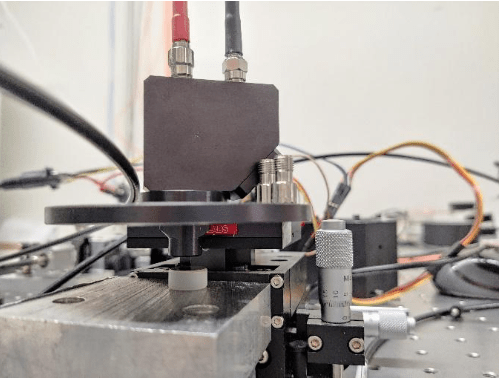

NLIR has made a close-contact probe for small samples as seen in the picture above. Light enters through one fiber and is transmitted to the sample with a spot size equal to the fiber size. Using a 400 μm fiber, a 400 μm spot size was achieved at a sample height of 4 mm from the tip of the probe. The light is reflected on the sample and guided back to the other fiber through which it reaches a spectrometer. This probe is ideal for small samples, for example on a wafer.

Interested in learning more about how our products can help you in your application?