Sorting of Black Plastic

In a world with a circular economy, it is crucial to reduce the amount of waste and recycle existing plastic resources. A lot of recycling technologies have been developed around plastic sorting, but black plastic remains a big challenge.

‘Plastic identification is made possible with near-infrared spectroscopy, which is able to sort a variety of plastics with a high degree of accuracy. Black plastic, on the other hand, is completely undetectable and poses many difficulties in research and practical applications.’

Mid-infrared spectroscopy can lead to new opportunities for reducing and recycling plastics

The current technological standard for sorting plastics is using near-infrared (NIR) spectrometers that measure light from a light source reflected on the plastic surface. Unfortunately, black plastics, which are widely used in both households and industry, cannot be sorted by NIR light. This is because they absorb all incident light and leave nothing to be detected. Therefore, black plastics often end up in landfills or are burned rather than recycled, posing a high environmental and health risk.

In contrast, mid-infrared (MIR) light is not absorbed by black plastics to the same degree as NIR light, enabling color-neutral plastic identification. Thus, a sorting facility based on MIR light has the possibility of recycling black plastics on an equal footing with other plastics.

Requirements for measuring reflection spectra of plastics

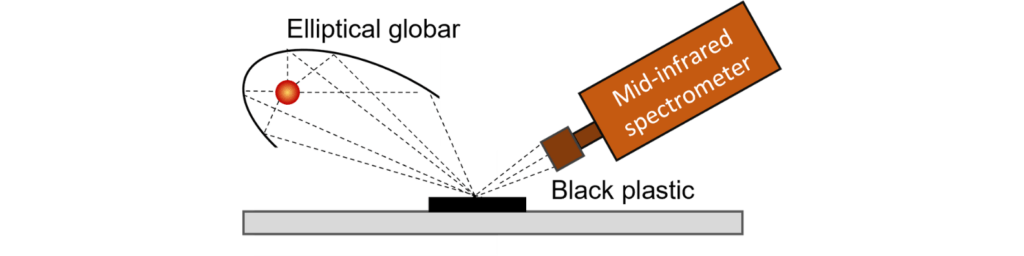

Plastics are measured with a light source and a spectrometer in a reflection setup as shown in the figure below. Plastic foils thinner than a few hundred µm may be measured in transmission, which makes the process easier, but all other plastics must be assessed in reflection.

Globars are most commonly used as light sources because it is easy and cheap to cover an area of cm in size with a large amount of broadband light. Laser sources are not straightforward to use in practical situations, even broadband laser sources, because of the inhomogeneity and unpredictable shape of most plastic samples, which causes the light to be reflected in arbitrary directions.

MIR spectrometers exist in many versions with many different properties. For research purposes, the most critical properties of a mid-infrared spectrometer are resolution, sensitivity, and stability. These high-end spectrometers are available from a range of suppliers. For plastic identification applications, however, these properties are of course desirable, especially sensitivity, but just as significant are robustness to the surrounding environment, price, and perhaps most importantly speed.

In a plastic sorting line with many samples passing by quickly, it is of very high importance that:

- the spectrometer’s sensitivity is high enough. Black plastics reflect only small amounts of light; a spectrometer must be sensitive enough to give out useful data from each sample.

- the speed is high enough to identify plastics on a fast-moving conveyor belt. Most conventional MIR spectrometers measure spectra at rates of 1 – 10 Hz; for plastic sorting, much higher speeds are needed for effective sorting of all plastic waste, for example, 100 Hz.

- a spectrometer can run undisturbed by high (or low) temperatures and unavoidable vibrations present in a sorting facility. This is the foremost obstacle to bringing conventional FTIR instruments to use in industry in general.

NLIR's solution in black plastic sorting

NLIR’s mid-infrared spectrometer S2050 series is designed to fit into an industrial setting: it’s the fastest mid-infrared spectrometer commercially available and it has no moving parts, making it very vibration tolerant. In addition, it is fiber-coupled, very sensitive, and has high resolution for many applications.

Spectra of black plastic using NLIR technology

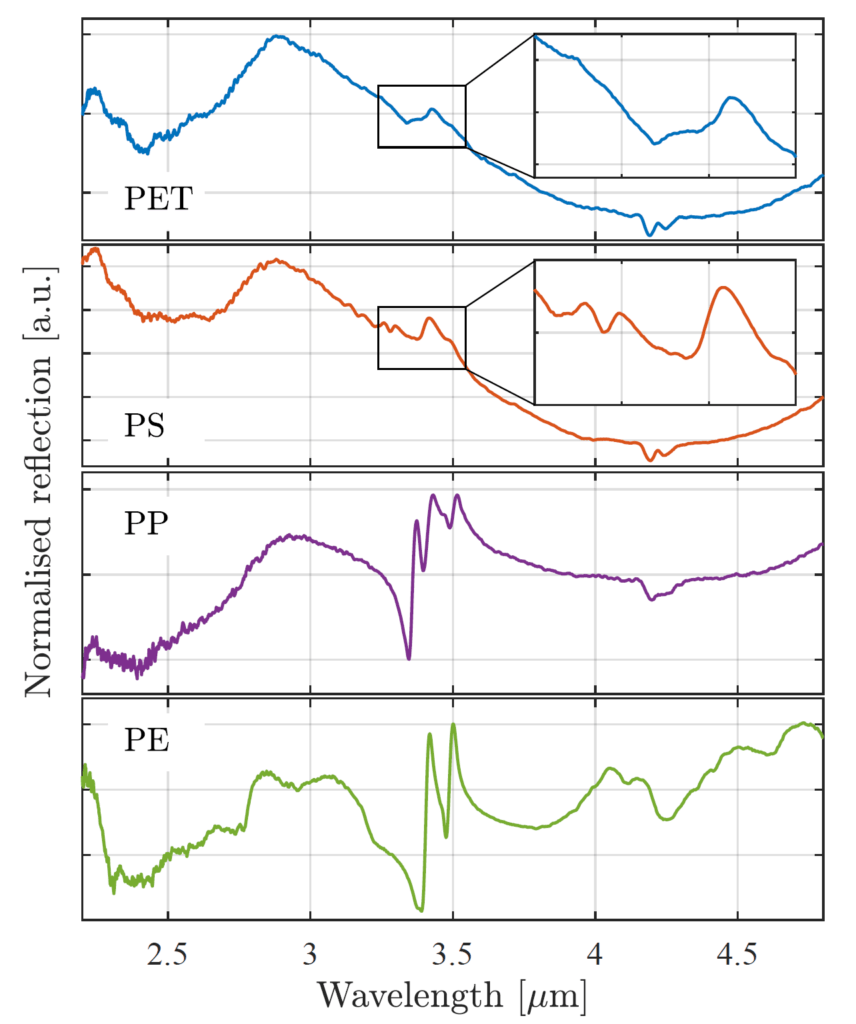

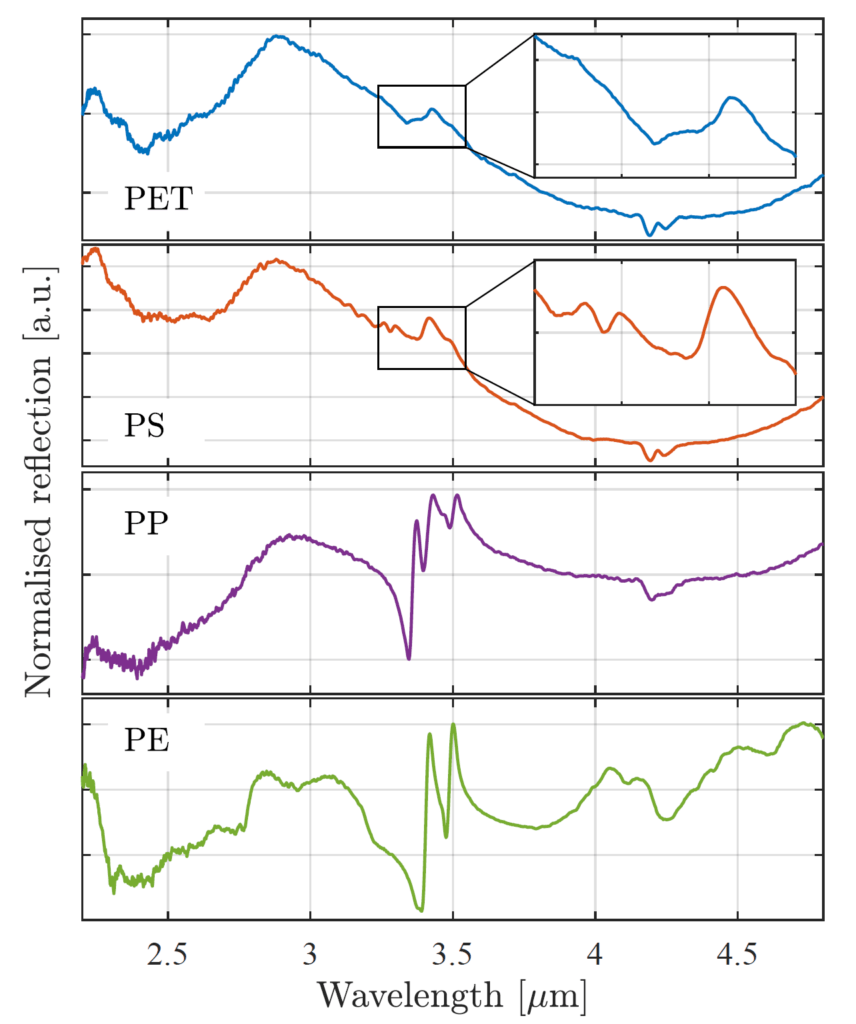

Reference spectra for plastics measured in reflection are not easy to use in a specific measurement situation. This is because the measured spectrum in practice is likely to depend on the angle and shape of the piece of plastic in question. NLIR has measured the reflection spectra of many different plastics using a globar light source and the S2050 spectrometer; the figure to the right shows examples of the four most common household plastics, polyethylene terephthalate (PET), polystyrene (PS), polypropylene (PP), and polyethylene (PE). It’s evident from these spectra that the most interesting region is 3 – 4 µm but more generally 2.5 – 4.5 µm is desirable for plastic sorting.

Spectra of black plastic using NLIR technology

Reference spectra for plastics measured in reflection are not easy to use in a specific measurement situation. This is because the measured spectrum in practice is likely to depend on the angle and shape of the piece of plastic in question. NLIR has measured the reflection spectra of many different plastics using a globar light source and the S2050 spectrometer; the figure to the right(?) shows examples of the four most common household plastics, polyethylene terephthalate (PET), polystyrene (PS), polypropylene (PP), and polyethylene (PE). It’s evident from these spectra that the most interesting region is 3 – 4 µm but more generally 2.5 – 4.5 µm is desirable for plastic sorting.

The next step is to teach an algorithm to know the difference between these acquired spectra.

NLIR in real-life plastic sorting

Together with NLIR, Michigan Technological University (MTU) proved that black plastics can be effectively and accurately categorized using fast mid-infrared spectroscopy (find the research paper here). With a simple globar light source in an elliptical reflector, NLIR’s S2050 fiber coupled spectrometer, and a taught categorizing algorithm developed by MTU, many different stationary plastics were identified at a rate of 200 Hz.

The combination of a smart algorithm and accurate data enabled the system to correctly identify all pieces of test plastic. In a newer study, the same system was used to measure and identify moving plastic particles, simulating a real sorting situation. Plastics moving 10 cm/s were identified with near 100% accuracy at 100 Hz acquisition (find the research paper here).

Our products offer a unique combination suitable for the darkest samples, the lowest concentrations, and the fastest reactions. Find out more about NLIR’s products.